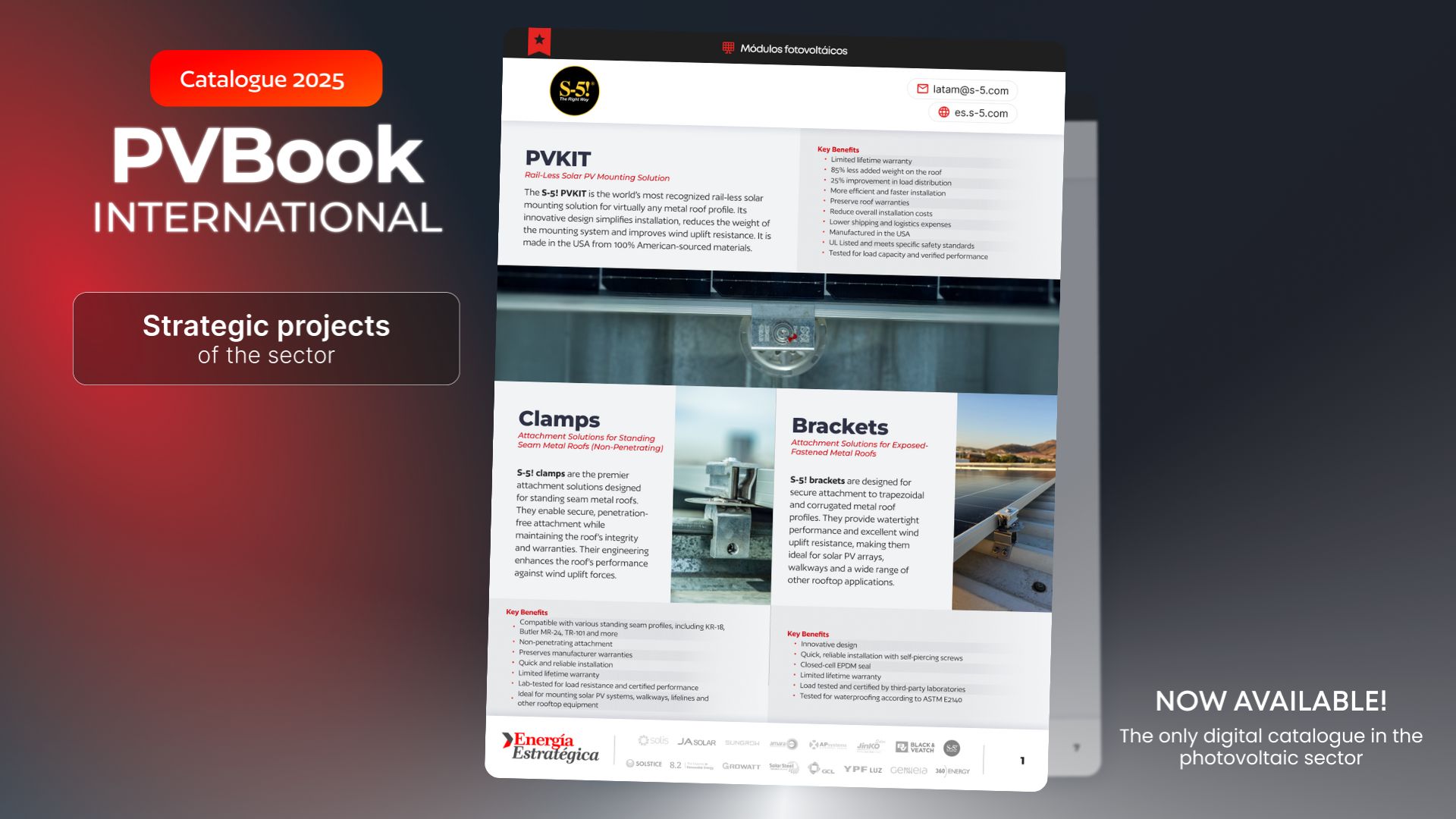

Weight reduction, structural preservation, and operational efficiency are the cornerstones of the solution S-5! proposes for mounting photovoltaic systems on metal roofs. Its flagship product, the PVKIT® , is the world’s first system to eliminate the need for rails in securing solar modules, optimizing resources in both logistics and on-site.

The PVKIT® allows for direct, drill-free installation , a critical advantage for the solar industry seeking to prevent leaks and maintain the structural integrity of roofs. Its design is geared towards achieving a strong, fast, and durable attachment, compatible with a wide variety of metal roofs, including curved, trapezoidal, and corrugated surfaces.

“The system preserves the integrity of the roof, maintaining the warranty thanks to its installation without perforations,” S-5! highlights in PVBook 2025, the international digital catalog prepared by Energía Estratégica that brings together technical data sheets, brand strengths and international experiences that show how innovation translates into real projects.

The S-5! system is delivered with pre-assembled parts , which facilitates transport, reduces the overall volume — to only 10% of that required by rail-based structures — and significantly decreases the carbon footprint.

This feature reduces installation times by at least 30% , allows for cleaner assembly, minimizes the amount of personnel required on site, and reduces the carbon footprint by 85%.

With just three components, PVKIT® is 85% lighter than traditional systems and distributes the structural load 25% better , making it an ideal solution for projects with weight restrictions or structural limitations, such as industrial buildings or roofs without intermediate support.

A compelling example of its applicability was realized in San Pedro Sula, Honduras , where the largest curved-roof solar installation in Central America was developed : a 2.46 MW system distributed across 27 self-supporting standing seam roofs within an industrial park. The project was executed by SEL Energía , the solar division of Dicoma Corporación .

The installation was carried out under demanding technical conditions: no possibility of placing additional support structures, with strict load restrictions and not allowing more than three operators simultaneously on each roof.

The solution combined the PVKIT® system with the S-5-H™ Mini clamp , achieving a direct and secure attachment without affecting the curvature or watertightness of the roofing sheets. This solution not only met the client’s structural and aesthetic requirements but also significantly reduced installation time and costs.

“Representing only 10% of the volume of traditional systems, it is also easier to transport to the installation site,” explains S-5!.

In terms of certifications, the system is UL listed , has undergone load testing validated by independent laboratories, and is 100% manufactured in the United States , guaranteeing industrial-grade quality standards for applications in demanding markets. Furthermore, S-5! offers a lifetime warranty on its components.

Therefore, in a context where photovoltaic projects require maximum efficiency without compromising safety, S-5! delivers a proven solution that innovatively addresses the technical and logistical challenges of the solar sector. And thanks to PVKIT®, developers can move forward with their installations more quickly, with less risk, and with tangible savings in installation and transportation costs .