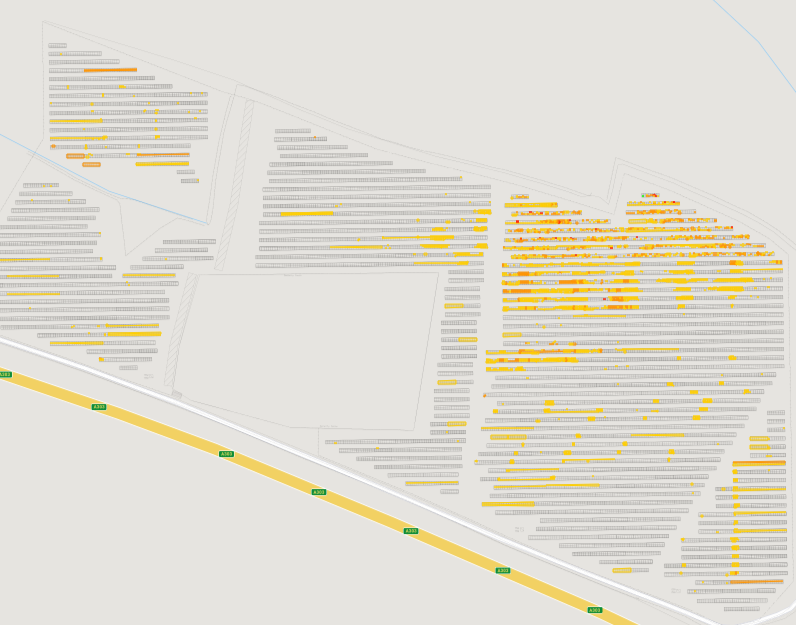

Digitalization applied to solar asset management is proving to have a tangible and measurable impact on operational and financial efficiency in the sector. A recent success story shows how a 7 MW photovoltaic plant recovered $268,000 through a warranty claim process, after detecting thousands of manufacturing defects in its modules.

The technical discovery was made possible by a high-definition thermal inspection and the implementation of SolarGain, Above’s digital platform, with a total investment of only $4,000. The tool enabled the client to identify, validate, and document—using georeferenced data—a total of 3,940 defective modules, streamlining the manufacturer’s response and turning a specific finding into a value recovery strategy.

In an interview with Energía Estratégica, Alejandro Cebrián, Sales Manager for Southern Europe and LATAM at Above, explains how the process was structured and which key elements can help replicate this model in other plants across the region.

Regarding the case mentioned, what types of thermal and visual anomalies were detected during the aerial inspection that triggered the warranty claim process, and what procedure was followed to document these anomalies to the manufacturer?

This client, during the second year of asset operation, discovered serious defects following its annual thermal inspection. After reviewing the results, the client conducted an on-site inspection of the most affected areas and found that many of the anomalies were related to lamination issues in the modules, causing temperature gradients of 5 to 15 degrees.

What were the distinguishing elements provided by Above’s digital solutions—particularly SolarGain and high-definition inspections—in terms of traceability, technical evidence, and claim validation with the manufacturer?

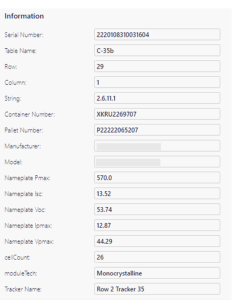

After the IEC-62446 thermal analysis by Above, the client used the SolarGain platform and SG app to create a Digital Twin of the plant.

The Digital Twin is a digital recreation of all plant components—modules, inverters, transformers, etc.—allowing for centralized, georeferenced, digital integration of all information for each component.

To carry out the analysis, the client followed these steps:

First, they uploaded all scanned serial numbers of the modules to the portal. If traceability had not been previously established, they could also have scanned them using the SolarGain app.

Second, they associated the corresponding visual inspections with each module in the Digital Twin, integrating module data, as well as visual and thermal images.

Once the information was fully integrated in a georeferenced way, the client noticed that most affected modules belonged to the same batch number. The portal then allowed them to easily filter by that batch and identify 3,940 modules to be claimed.

Finally, the client automatically exported a PDF list of the affected modules from Above and sent it to the manufacturer within minutes.

What economic or logistical impact did this process have for the client, and how did your technologies help accelerate or streamline the process with the panel supplier?

With an investment of approximately $4,000 in thermography and the platform, the client was able to detect and claim roughly $268,000. Such defect detection would have been difficult without integrated traceability and georeferencing.

In addition to the financial return, the process saved an estimated 87% of the time usually required to prepare a report—what took just one day using SolarGain and its automatic reporting would have taken weeks using traditional methods.

Based on this experience, what key lessons can other companies in the region adopt to structure successful warranty claim processes using remote inspection and georeferenced analysis tools?

Undoubtedly, the main takeaway is that investing in digitalization leads to time and cost savings while improving the quality of information management in asset operations.

Regarding this success story and in general terms, how do you assess the potential of autonomous drone systems in continuously improving processes related to predictive maintenance and support for claims?

The potential is immense. Autonomous drones reduce time and costs, improve response times, and professionalize incident management. Moreover, their integration with artificial intelligence and platforms like Above makes them strategic tools for digital transformation in maintenance and after-sales service.